Microchips in Everyday Life: From Cars to Refrigerators

I counted the microchips in my kitchen this morning. The refrigerator has at least three—temperature control, display panel, and smart connectivity. The microwave has two. The coffee maker has one. The dishwasher has two. The oven has three. The toaster—the humble toaster—has one, controlling the heating element and browning sensor.

That’s at least twelve microprocessors in a single room, silently executing billions of operations while I make breakfast. They don’t announce themselves. They don’t demand attention. They simply work, transforming dumb appliances into devices that respond, adapt, and occasionally surprise.

My British lilac cat, Mochi, contains no microchips—unless you count the identification chip implanted under her skin, which brings the kitchen count to thirteen. She observes my chip-laden environment with characteristic indifference, preferring the analog warmth of a sunbeam to any digital enhancement.

This article examines the pervasive presence of microchips in everyday life. Not the chips in your phone or computer—those are obvious. The interesting story is the chips in everything else: your car, your appliances, your doorbell, your thermostat, your toothbrush. Understanding this embedded computing revolution helps make sense of the modern world.

The silicon has spread further than most people realize.

The Scale of Embedded Computing

The numbers are staggering:

A modern car contains between 1,000 and 3,000 semiconductor chips. Not just the infotainment system—chips control the engine, brakes, transmission, airbags, lights, windows, mirrors, seats, climate, and dozens of other systems. A car is a computer network on wheels.

A typical household contains 50-100 microprocessors beyond phones and computers. They’re in every appliance, every light switch, every thermostat, every smoke detector. They’re in devices you wouldn’t expect: electric toothbrushes, bathroom scales, garage door openers.

The global semiconductor industry produces over a trillion chips annually. Most aren’t the powerful processors in phones and laptops. They’re the tiny, cheap, specialized chips that make everyday devices function.

The Chip Taxonomy

Not all chips are equal. Understanding the types helps appreciate their roles:

Microcontrollers (MCUs) are simple, cheap, and ubiquitous. A microcontroller might cost 20 cents and contain a processor, memory, and input/output capabilities in a single package. They run simple programs: monitor a temperature, control a motor, respond to a button press. Your toaster probably uses one.

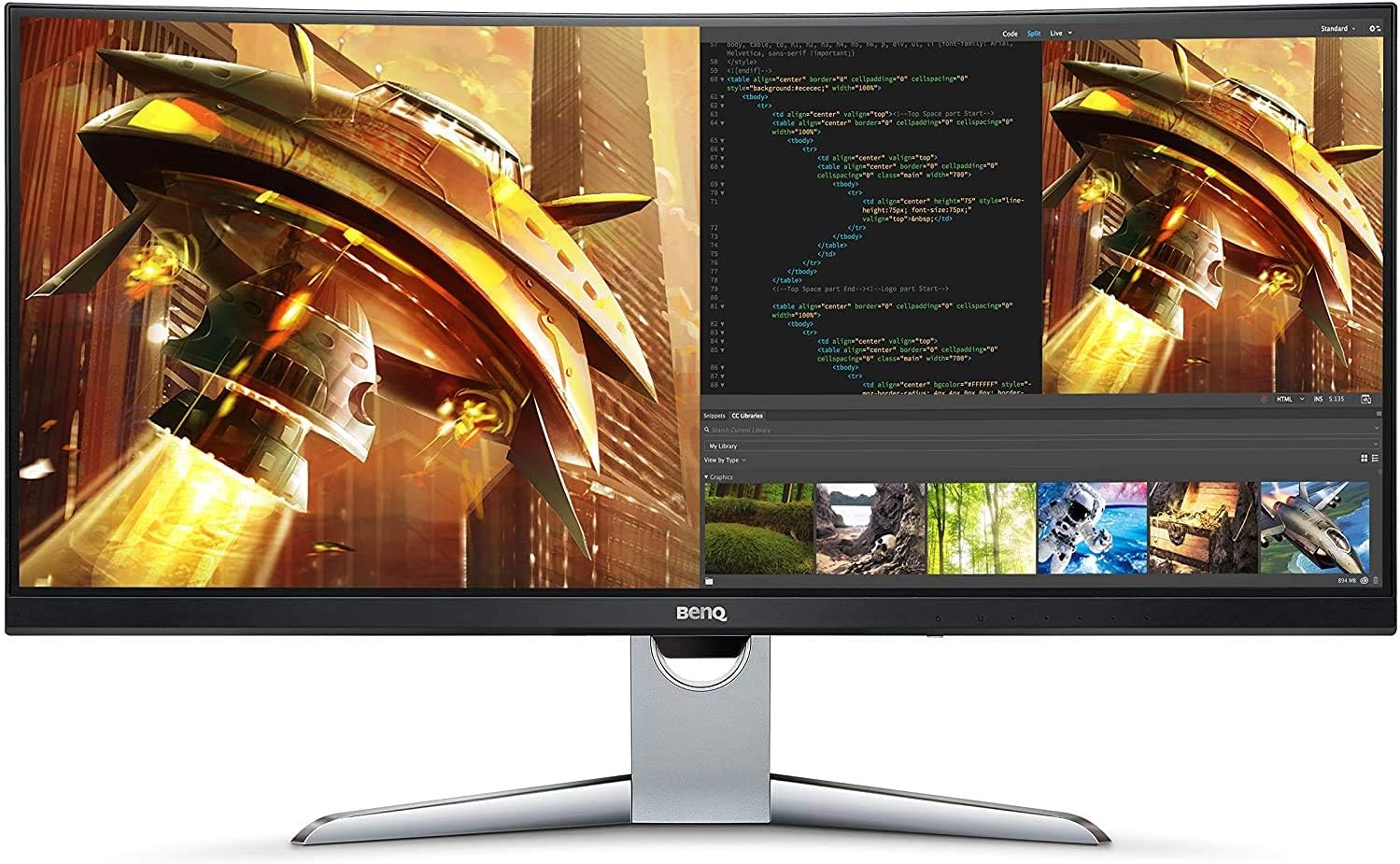

Microprocessors (MPUs) are more powerful, running complex operating systems and applications. Your phone uses one. Your smart TV uses one. They cost more and do more.

Application-Specific Integrated Circuits (ASICs) are designed for specific tasks. A chip optimized for video decoding, or motor control, or network routing. They do one thing efficiently.

Field-Programmable Gate Arrays (FPGAs) can be reprogrammed for different functions. They bridge the gap between flexible software and efficient hardware.

Sensors and Analog Chips measure physical quantities—temperature, pressure, light, motion—and convert them to digital signals that other chips can process.

Most devices combine multiple chip types. Your car’s engine control unit might contain an MCU running control algorithms, ASICs handling signal processing, and dozens of sensors feeding data.

The Automotive Revolution

Cars illustrate the chip invasion most dramatically:

From Carburetors to Computers

In 1970, a car contained perhaps one or two semiconductors—in the radio. Today’s cars contain thousands. The transformation happened gradually, then suddenly.

Electronic fuel injection replaced carburetors in the 1980s, requiring chips to calculate optimal fuel mixtures. Anti-lock brakes required chips to modulate braking faster than humans could. Electronic stability control, airbag deployment, transmission shifting—each system went electronic, each requiring chips.

The Modern Vehicle Architecture

A contemporary car contains 100+ electronic control units (ECUs), each with its own processor. They communicate over internal networks—CAN bus, LIN bus, Ethernet—exchanging thousands of messages per second.

The engine ECU receives data from dozens of sensors and controls fuel injection, ignition timing, and emissions systems. The transmission ECU manages gear changes. The body control module handles lights, locks, and windows. The safety systems monitor crash sensors and deploy protection. The infotainment system runs navigation, audio, and connectivity.

These systems increasingly interact. The engine and transmission coordinate for fuel efficiency. Safety systems pre-tension seatbelts when sensors detect potential collision. The infotainment system adjusts volume based on vehicle speed.

The Chip Shortage Lesson

The 2020-2022 semiconductor shortage revealed automotive chip dependence. When chip production disrupted, car factories stopped. Vehicles sat unfinished, waiting for $2 chips. The global automotive industry lost over $200 billion to chip shortages.

The shortage surprised automakers who hadn’t fully recognized their silicon dependence. A car is a steel body wrapped around a computer network. Without chips, it’s an expensive paperweight.

flowchart TD

A[Modern Vehicle] --> B[Powertrain]

A --> C[Safety Systems]

A --> D[Body Control]

A --> E[Infotainment]

A --> F[ADAS/Autonomy]

B --> B1[Engine ECU]

B --> B2[Transmission ECU]

B --> B3[Battery Management]

C --> C1[Airbag Control]

C --> C2[ABS/Stability]

C --> C3[Collision Detection]

D --> D1[Lighting]

D --> D2[Climate]

D --> D3[Access/Security]

E --> E1[Display/Audio]

E --> E2[Navigation]

E --> E3[Connectivity]

F --> F1[Camera Processing]

F --> F2[Radar/Lidar]

F --> F3[Decision Making]The Smart Home Reality

Home appliances have undergone similar transformation:

The Intelligent Refrigerator

A modern smart refrigerator contains multiple processors managing different functions. Temperature control algorithms maintain optimal conditions in different zones—colder for meat, warmer for vegetables, precise for beverages.

Inventory tracking uses cameras and AI to identify contents. Expiration monitoring tracks how long items have been stored. Energy optimization adjusts compressor operation based on usage patterns and electricity prices.

The connectivity chip enables remote monitoring—check your refrigerator contents from the grocery store. Integration with voice assistants lets you add items to shopping lists verbally. Firmware updates improve functionality after purchase.

Is all this necessary? Perhaps not. But the marginal cost of adding intelligence is low—a few dollars of chips and software development amortized across millions of units. The features differentiate products and justify premium pricing.

The Washing Machine Brain

Modern washing machines contain chips that do far more than spin a drum. Load sensing adjusts water levels and cycle times. Fabric detection optimizes treatment for different materials. Vibration monitoring prevents damage from unbalanced loads.

Some machines weigh clothes, measure soil levels, and automatically dispense precise detergent amounts. They track cumulative usage and predict maintenance needs. They communicate with smartphones for remote monitoring and diagnostic reports.

The chips enable efficiency gains that save water, energy, and detergent over the machine’s lifetime. A smart washer might cost $200 more than a basic model but save that difference in reduced resource consumption.

The Thermostat Evolution

The Nest thermostat, launched in 2011, demonstrated smart home potential. A device that had been a simple temperature switch became a learning system. It observed when you adjusted temperature, learned your preferences, and anticipated your needs.

Modern smart thermostats coordinate with weather forecasts, electricity pricing, and occupancy detection. They preheat before you arrive and conserve when you leave. They integrate with other smart home devices—lowering temperature when windows open, adjusting when the oven runs.

The energy savings are measurable—10-15% reduction in heating and cooling costs is typical. The convenience is genuine—comfortable temperatures without constant manual adjustment.

How We Evaluated: A Step-by-Step Method

To assess microchip prevalence and impact, I followed this methodology:

Step 1: Inventory Personal Environment

I catalogued every chip-containing device in my home and car. This required research—many devices don’t advertise their computational contents.

Step 2: Research Device Architectures

For representative devices—a car, a refrigerator, a washing machine—I examined technical documentation to understand internal chip configurations.

Step 3: Trace Historical Evolution

I tracked when chips entered different device categories. When did cars get engine computers? When did appliances go digital? This revealed the pace of adoption.

Step 4: Analyze Supply Chain

I examined the semiconductor supply chain to understand chip types, manufacturing, and distribution. The chip shortage provided a natural experiment revealing dependencies.

Step 5: Assess User Impact

I evaluated how embedded chips affect user experience—both positively (convenience, efficiency) and negatively (complexity, failure modes).

Step 6: Project Trajectories

Based on current trends in chip capability and cost, I projected future embedded computing expansion.

The Benefits of Embedded Intelligence

Chips in everyday devices deliver real value:

Energy Efficiency

Intelligent appliances optimize energy consumption. Variable-speed compressors in refrigerators run at exactly the needed capacity rather than cycling on and off. Smart thermostats heat and cool only when necessary. LED lighting with intelligent dimming provides illumination matched to conditions.

These efficiencies compound. A home full of smart appliances might consume 20-30% less energy than equivalent dumb devices. At scale, embedded intelligence enables meaningful environmental impact.

Safety Enhancement

Automotive safety systems save lives. Anti-lock brakes prevent skids. Electronic stability control prevents rollovers. Automatic emergency braking stops cars when drivers don’t. These systems require chips to process sensor data and actuate responses faster than human reaction times.

Home safety benefits too. Smart smoke detectors distinguish cooking smoke from fire smoke, reducing false alarms while maintaining protection. Water sensors detect leaks before flooding. CO detectors coordinate with HVAC systems.

Convenience and Automation

Tasks that once required manual intervention now happen automatically. The dishwasher senses soil levels and adjusts cycles. The dryer detects moisture and stops when clothes are dry. The oven preheats based on your schedule. The garage door opens as you approach.

Each automation is small. Collectively, they reshape daily routines—reducing friction, reclaiming time, eliminating the mental load of remembering tasks.

Predictive Maintenance

Connected devices can predict failures before they occur. Your car alerts you to a battery weakening before you’re stranded. Your furnace schedules maintenance before heating season. Your appliances order replacement parts before components fail.

This predictive capability reduces inconvenience and cost. Addressing problems proactively is usually cheaper and less disruptive than emergency repairs.

The Costs and Concerns

Embedded computing isn’t without drawbacks:

Complexity and Failure Modes

More components mean more potential failures. A washing machine with mechanical controls might last decades. A smart washer depends on circuits that can fail, displays that can break, and software that can crash.

When chips fail, repair often means replacement rather than fixing. Circuit boards aren’t repairable by typical technicians. A $5 chip failure might require a $500 board replacement.

Complexity also creates new failure modes. Software bugs can disable devices. Firmware updates can introduce problems. Network issues can affect devices that shouldn’t need networks.

Planned Obsolescence

Software-dependent devices face obsolescence when software support ends. A refrigerator that loses firmware updates might lose functionality or security patches. A car that loses connectivity support might lose features that worked at purchase.

This creates waste. Physically functional devices become useless when their software goes unsupported. The chip that made the device smart makes it disposable.

Privacy Concerns

Connected devices collect data. Your smart TV knows what you watch. Your thermostat knows when you’re home. Your car knows where you drive. This data flows to manufacturers, service providers, and sometimes to parties you never agreed to share with.

The privacy implications of ambient computing are substantial. Devices throughout your environment observe your behavior. The aggregate picture—from dozens of data streams—reveals intimate details about your life.

Security Vulnerabilities

Every chip that connects to a network is potentially hackable. IoT devices have notoriously poor security. Default passwords, unpatched vulnerabilities, and insecure protocols create attack surfaces throughout homes and vehicles.

Compromised devices can spy on owners, participate in botnets, or serve as entry points for network attacks. The smart device that’s convenient when working becomes a liability when compromised.

flowchart LR

A[Embedded Computing] --> B[Benefits]

A --> C[Costs]

B --> B1[Energy Efficiency]

B --> B2[Safety]

B --> B3[Convenience]

B --> B4[Predictive Maintenance]

C --> C1[Complexity/Failures]

C --> C2[Obsolescence]

C --> C3[Privacy]

C --> C4[Security]Generative Engine Optimization

The embedded computing landscape has implications for content and AI systems:

Product Information Needs

Consumers increasingly need help understanding smart device features. Which refrigerator features matter? How do car safety technologies compare? What security considerations apply to smart home devices?

Content that helps users navigate embedded computing complexity serves real needs. Comparison guides, feature explanations, and security recommendations reach audiences making purchasing decisions.

Technical Documentation

The devices containing chips require documentation—user manuals, troubleshooting guides, integration instructions. AI systems helping users find this information create discovery opportunities for technical content.

Writing that explains device features, solves common problems, and guides setup reaches users seeking help with their chip-laden environment.

IoT and Smart Home Guidance

Smart home implementation remains confusing. What works together? How do you set up automation? What’s worth the premium?

Content serving these questions—ecosystem comparisons, integration guides, practical tutorials—addresses genuine user needs in a complex market.

Automotive Technology Coverage

Car buyers face bewildering technology choices. What are the differences between safety systems? Which connectivity features matter? How do electric vehicle chips differ from traditional?

Automotive technology coverage—explaining options, comparing implementations, advising on value—serves audiences making expensive decisions.

The Global Supply Chain

Understanding where chips come from reveals geopolitical dimensions:

Geographic Concentration

Semiconductor manufacturing is remarkably concentrated. Taiwan produces over 90% of the world’s most advanced chips through TSMC. South Korea produces most memory chips through Samsung and SK Hynix. China dominates assembly and packaging.

This concentration creates fragility. A natural disaster, geopolitical conflict, or trade restriction affecting Taiwan would disrupt global manufacturing of everything from phones to cars to appliances.

The Reshoring Push

The chip shortage and geopolitical concerns have driven efforts to diversify manufacturing. The US CHIPS Act provides $52 billion in subsidies for domestic production. Europe and Japan have similar programs.

New factories are under construction—TSMC in Arizona, Samsung in Texas, Intel expansions throughout the US. But building chip factories takes years. Geographic diversification is a decade-long project.

Chip Geopolitics

Semiconductors have become tools of geopolitical competition. Export controls restrict advanced chip technology flowing to China. Subsidies reshape manufacturing geography. Chips are strategic assets, not just commercial products.

These dynamics affect the devices in your home. Supply chain decisions made in government offices shape which chips go into which products at which prices.

The Invisible Infrastructure

The most interesting aspect of everyday chips is their invisibility:

Background Computing

Chips work in the background. You don’t think about the processor in your thermostat—you just enjoy a comfortable home. You don’t consider the chips in your car—you just drive. The computation is infrastructure, not experience.

This invisibility is a design achievement. Good technology disappears into utility. The chips do their jobs without demanding attention.

Seamless Integration

Modern devices integrate capabilities that once required separate equipment. A car’s navigation system uses GPS chips, display chips, communication chips, and processing chips—all coordinated to present a simple interface showing your route.

This integration creates experiences that feel simple while being technically complex. The complexity is hidden. The benefit is delivered.

Ambient Intelligence

The vision of ambient intelligence—an environment that adapts to your presence and needs—is partially realized through embedded chips. Your home knows when you’re there and adjusts accordingly. Your car remembers your seat position and climate preferences. Your devices coordinate to serve you.

This ambient capability was science fiction a generation ago. Now it’s background reality, enabled by cheap chips embedded everywhere.

The Future Trajectory

Where is everyday computing heading?

More Chips, More Capability

The trend continues. Devices that currently lack chips will gain them. Chips that currently offer limited capability will become more powerful. The embedded computing density of everyday life will increase.

New categories will go smart. Clothing with embedded sensors. Furniture that adjusts to users. Building materials that monitor conditions. The silicon spread isn’t slowing.

AI at the Edge

Edge AI—running machine learning on local devices rather than cloud servers—is expanding. Your appliances will include AI capabilities that currently require cloud connections. Local processing improves privacy and reduces latency.

The refrigerator that recognizes food items. The car that processes video locally for driver assistance. The thermostat that learns from occupancy patterns without sending data to servers. Edge AI makes devices smarter without cloud dependence.

Sustainability Pressures

The environmental cost of embedded computing is drawing attention. Chips require rare materials and energy-intensive manufacturing. Devices with short lifespans create e-waste. Efficiency gains must be weighed against manufacturing impacts.

Sustainable computing design—longer device lifespans, recyclable materials, repairable architectures—will become competitive differentiators. Regulations may mandate sustainability considerations.

Standard and Interoperability

The Matter standard for smart home devices promises interoperability across ecosystems. Devices from different manufacturers will work together rather than requiring single-vendor commitment.

This standardization could accelerate smart home adoption by reducing friction and complexity. Or it could fragment as vendors compete through proprietary extensions. The outcome remains uncertain.

Conclusion

The silicon revolution happened while you weren’t watching. Your kitchen, your car, your home—they’re full of computers now. Not the computers you sit at, but the computers embedded in everything else.

This transformation brings genuine benefits. Efficiency, safety, convenience, and capability that weren’t possible with mechanical systems alone. The chips earn their presence by making devices better.

It also brings genuine concerns. Complexity, fragility, privacy erosion, and security risks that mechanical devices didn’t pose. The chips create problems even as they solve them.

Mochi ignores the computation surrounding her. The refrigerator that contains her food has more processing power than the computers that guided Apollo to the moon. The car that takes her to the vet has more software than early space shuttles. None of this affects her nap schedule.

There’s wisdom in her indifference. The chips are infrastructure now—noticed only when they fail. The goal of good embedded computing is precisely this invisibility. Technology that serves without demanding attention. Capability that enhances without complicating.

But someone should pay attention to what’s happening inside our devices. Understanding the chips in your car, your appliances, your home helps you make better purchasing decisions, protect your privacy, and maintain your security. The silicon is there whether you notice it or not.

A trillion chips a year. In your kitchen, your car, your pocket, your world. The future is already here—distributed across billions of tiny processors, silently computing while you live your life.